As a garments manufacturer, we are able to help you design your unique collections, find the expected fabric, make the detail garments size chart, seam the real sample, arrange the standard bulk operation, support various shipping methods, and pay attention to customer feedbacks after shipping.

What’s more, help you built your exclusive prodution team.

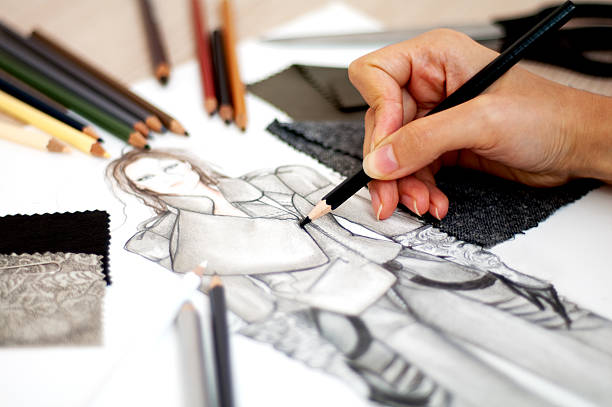

Help You Design Your Unique Collections

We will start to communicate with one of your ideas.

What kind of design do you want to make, tops, pants, dresses, coats or sweaters, etc.;

Then we can discuss styles, one-shoulder, tube top, halter neck, long sleeves , puff sleeves, loose, tight or others;

What kind of techniques are needed on it, pleats, embroidery, printing, drawstring, elastic, etc.

After confirming these, we have the original design drawing, and then we will adjust according to this design drawing, and finally get the desired design.

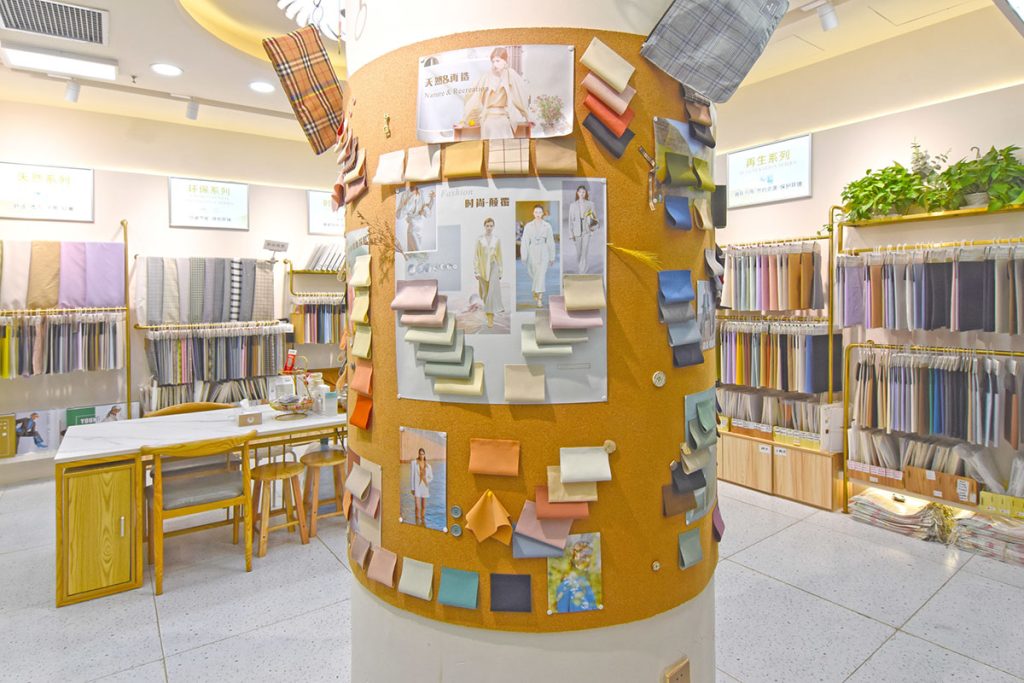

Help You Find the Expected Fabric

We are close to China’s largest fabric market, Zhongda Fabric Market, where there are tens of thousands of fabric stalls, and a series of supporting craft shops, such as pleating, embroidery, printing, dyeing, buttons, stamps, etc.

Our purchase team is looking for the fabric that customers want every day. If you already have the fabric you want, we will find the closest fabric according to your description.

If you are not sure what fabric to use, it doesn’t matter, our designers are similar to the one matching well based on the design we had made, and recommend some suitable fabrics for you, then take photos and videos for confirmation, until you find the fabric want to have.

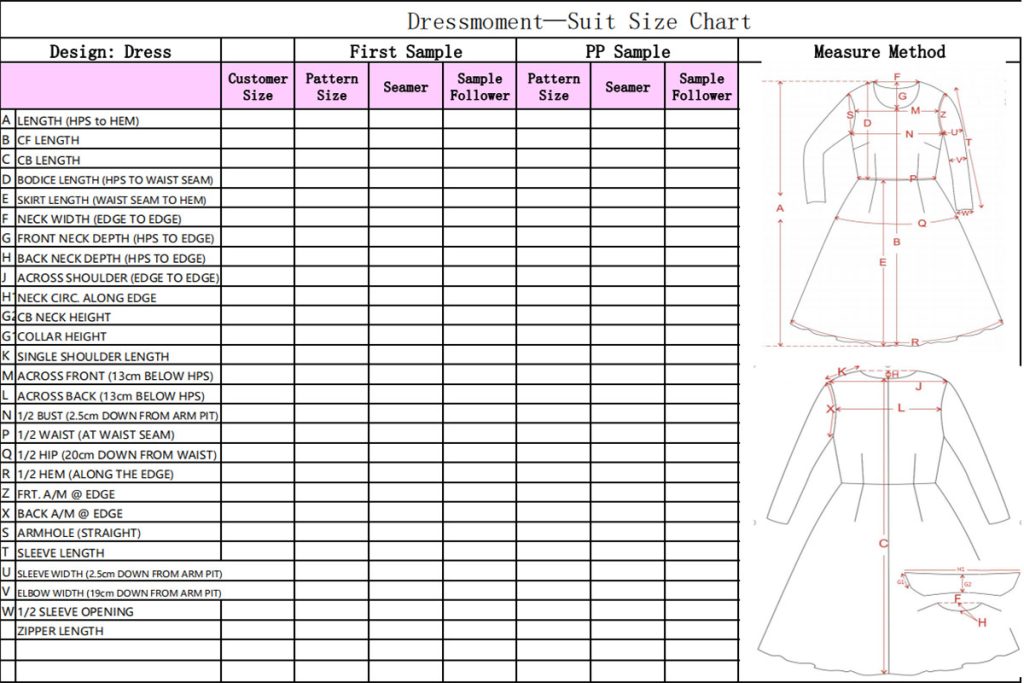

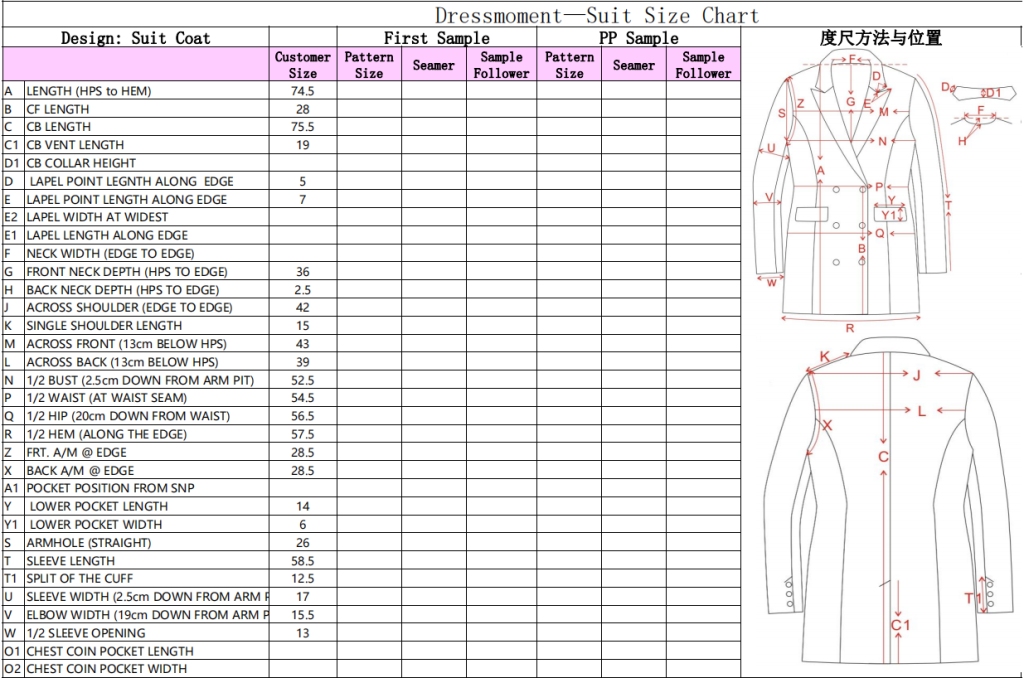

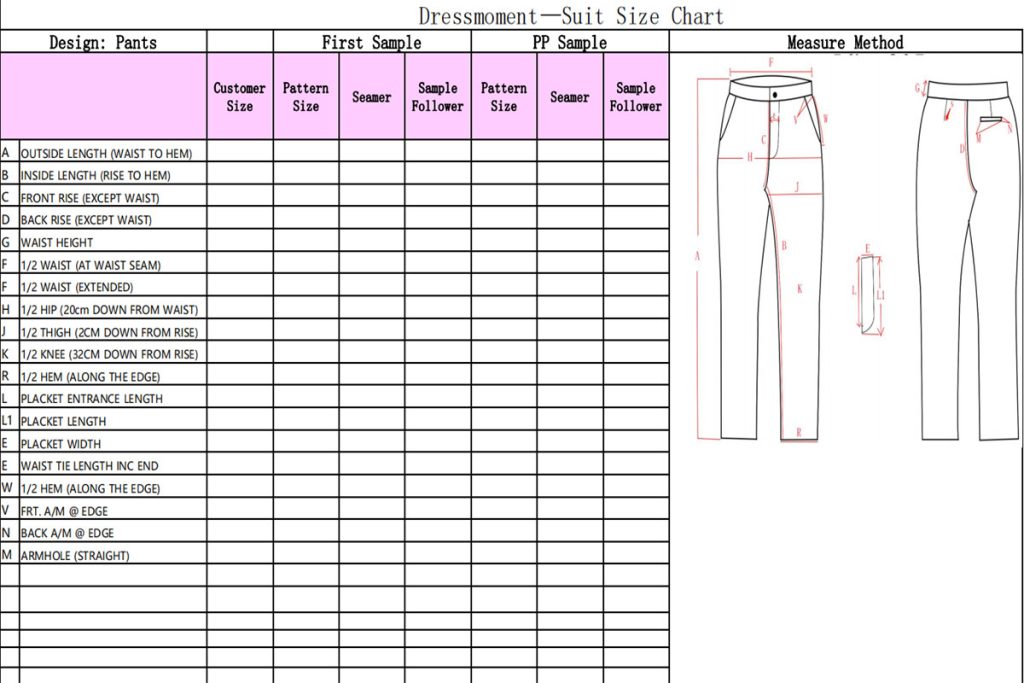

Help You Make the Detail Garments Size Chart

Size is a very important factor. If you have the size, we will produce it according to your size. If you don’t have the size, don’t worry, we will teach you,

First, you can choose a size from our size chart, we use the international size,

Second, we will teach you how to measure and what size you need, we can even send you a form that indicates what size you want and where to measure, and if that’s not enough, we also have pictures and text instructions , just follow the pictures and text to operate.

After the first operation, we will create an exclusive size table for you, and then operate according to this size table

Help You Seam the Real Sample

After confirming the size, we will check all the design requirements and fabrics again. If there is any modification, there is still time at this stage. After confirmation, we will give you a sample production plan to start purchasing fabrics and arrange to make paper patterns , if necessary, we can arrange 3D model production and confirm again.

After confirmation, start to arrange sewing, ironing after sewing is completed, and we will take pictures to confirm with you after ironing, and then return to the beginning confirm the design requirements one by one. If you feel that there is something inappropriate, we will modify it until all the points are confirmed. We will record the completion of the size, which is normally control within 1 cm.

If there is no problem with the size, we will start cutting and packing, and arrange to send out the sample.

If you feel that there is still room to modify after receiving it, we will arrange a PP version and 2 PP versions until you think it is ok.

Help You Arrange the Standard Bulk Operation

When you confirm that there is no problem with the sample and can be producted, we will enter mass production.

First of all, we will give you a mass production schedule, which will include sample confirmation time, fabric purchase time, bed cutting start time, sewing start time, mid-check time, sewing finish time, ironing time, thread clearing and Packing time, final check QC time, shipping time, we update the above informations once any step finished.

Fabric procurement: We will compare the bulk fabrics with the fabrics of the last sample. If the color difference is not obvious, we will arrange procurement. If there is no inventory or other problems, we will give feedback as soon as possible and arrange to find alternative fabrics and confirm with the customer.

Start cutting the bed: You need to confirm that the pattern is the same as the size chart. If the fabric will shrink, arrange to shrink first, and then start cutting, so that the size of the cut piece is the same as the size of the pattern, which will be conducive to sewing.

Production meeting: Before we start sewing, we will call the workers who produced this batch of goods to hold a production meeting, explain the customer’s requirements and points that need attention, and print out the information to the team leader.

Sewing: After the workers know the details, they start to sew. We will use machines to deal with some difficult places, such as plackets, such as pockets, to ensure that the lines will be very clean, straight and fast.

Mid-check: When finished products first appear, we will arrange mid-check personnel to check customer requirements to see if there are any differences, and ask for confirmation one by one. If there are any problems, we will immediately give feedback and confirm the modification plan.

Ironing: If there is no problem in the middle inspection, after the sewing is completed, start ironing, straighten some seams of the clothes, so that the shape and characteristics of the clothes are more obvious.

Final inspection: After the ironing is completed, the final inspection will start, and another group of people will start to check whether the finished product can meet the customer’s requirements, and whether the size is controlled within the scope of the customer’s requirements. This is usually a spot check, and a normal batch of 300 pieces More than 40 pieces must be drawn, and the overall pass can only be passed. If the proportion is unqualified, it must be returned to the sewing machine for rectification. Each final inspection needs to submit a QC report and explain the treatment plan.

In addition, if the customer has his own QC who wants to check the goods, we can pack them and wait for the customer’s QC to come to check.

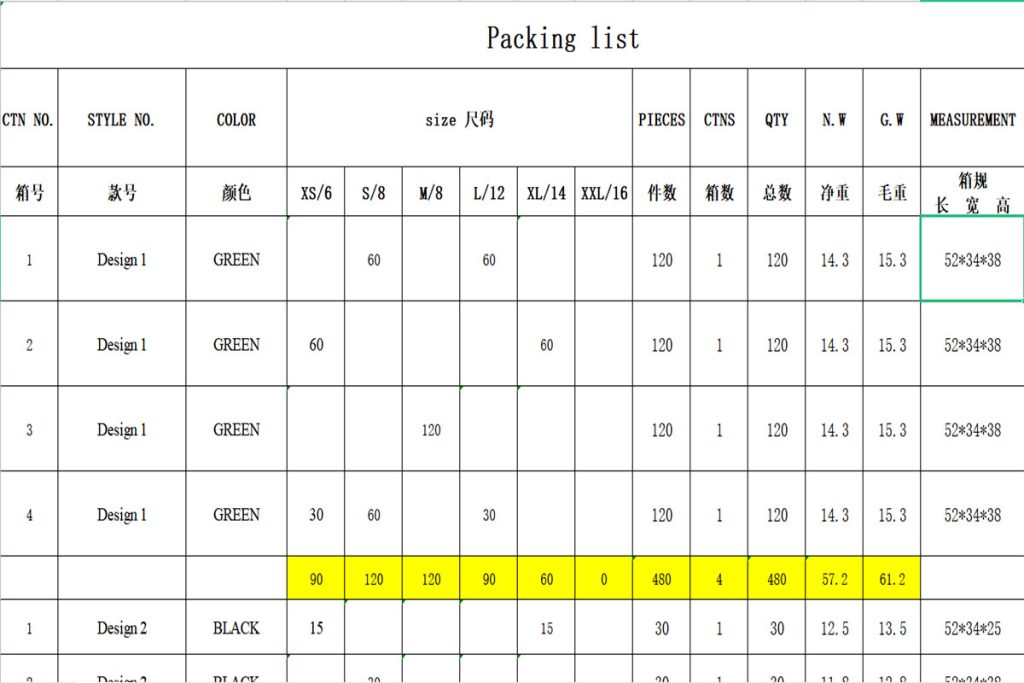

Packing: Pack and box qualified products, pack the box according to the size and weight required by the customer, paste two box marks on it, and write down the style, color, code number, quantity, weight, and customer information.

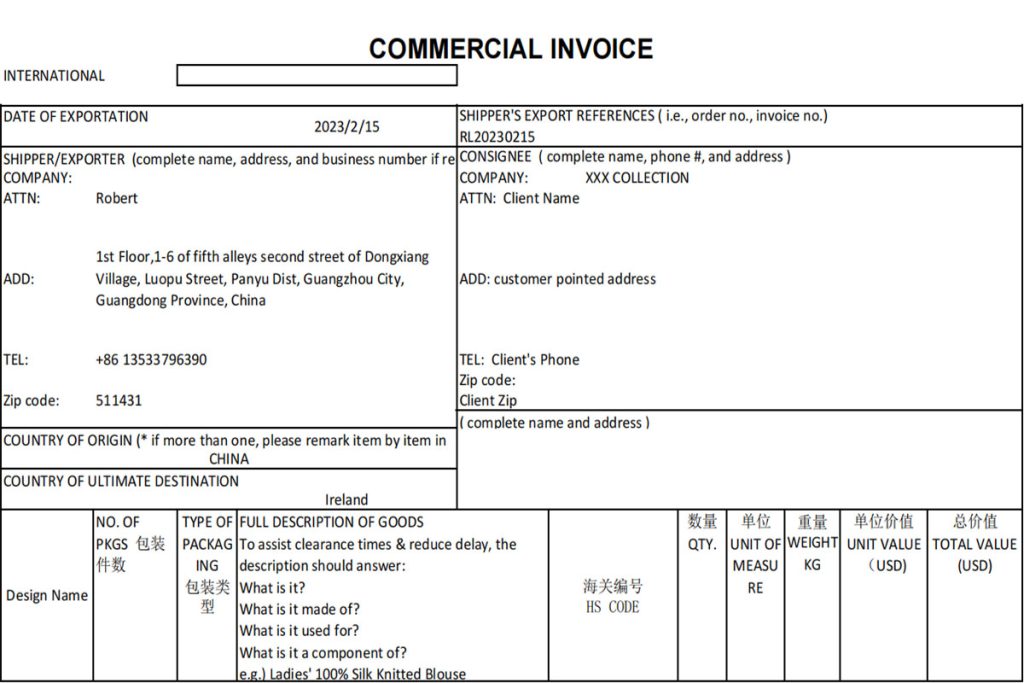

Support Various Shipping Method

We can arrange courier and air freight, usually one of Fedex, DHL, UPS, and it is expected to be delivered within 3 to 7 days.

We can also arrange shipping by sea, which is expected to take 25 to 35 days. We will prepare the packing list and commercial invoice, and you can just take it to the customs for customs clearance. During this period, if there is any problem, we will fully cooperate to solve it.